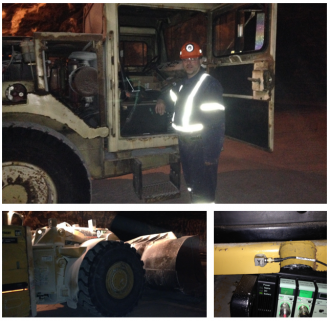

In an effort to ensure the health and safety of their employees, Windsor Salt brought in the engineering team at Akoustik Engineering to assess the whole body vibration (WBV) health risks as an outcome of continued operation of the loader vehicles in the underground mine. The associated risks of WBV include short-term effects such as nausea, headache and fatigue, as well as long terms effects including difficulties to move, disability, impairment and psychological problems. Two types of vehicles were identified as exhibiting potential health risks, the load-haul dump (LHD) and the ammonium nitrate and fuel oil (ANFO) loaders. For each of the two vehicle types, multiple vehicles were utilized as part of the assessment, each with a different tire type and arrangement. The primary focus of our study was to measure the vibration experienced by the operator inside the vehicle cabin and to quantify the maximum acceptable dosage that an operator should be exposed to for each tire type and vehicle combination. Windsor Salt has been involved with an ongoing investigation to select an optimum tire type and combinations that meet a broader set of criteria, including cost, safety and vibration impact, etcetera.

As mentioned, multiple vehicles were tested, each with a different tire type and combination, air or rubber type tire fill. The vehicle operators were instructed to drive the vehicles under normal operating conditions while carrying out their regular duties. To assess the impacts, a Brüel & Kjær (B&K) PULSE measurement system was used to acquire the data. A single tri-axial accelerometer was mounted to the driver’s seat frame and a tri-axial seat accelerometer pad was strapped to the topside the driver’s seat. A single microphone was also placed in the cabin of the vehicle. The purpose of this was for the driver to communicate his operation and movement of the vehicle during the data acquisition to allow for the subsequent correlation of the vehicle activities to the measured vibration data.

The acquired vibration data was post-processed using B&K PULSE Reflex software. The audio signals were sectioned into individual files in order to isolate the various individual operations of the vehicles as described by the operator into the microphone installed in the vehicle cab. The seat pad data was post-processed using the human vibration weighting factors, Wd(x and y) and Wk(z). From the results of the data, the daily exposure, A(8), was calculated for each of the vehicles tested. The maximum dosage below the action value and limit was also calculated. Given that the vibration impacts are not feasible to abate for this type and size of vehicle, the action value is essentially treated as the exposure time limit and thus restricts any further exposure to that employee. The results of the assessment also provided Windsor Salt with vital information pertaining to the preferred tire type and arrangement for their fleet of loaders.